Bogie Hearth Furnaces: The New Benchmark for Heat Treatment Equipment

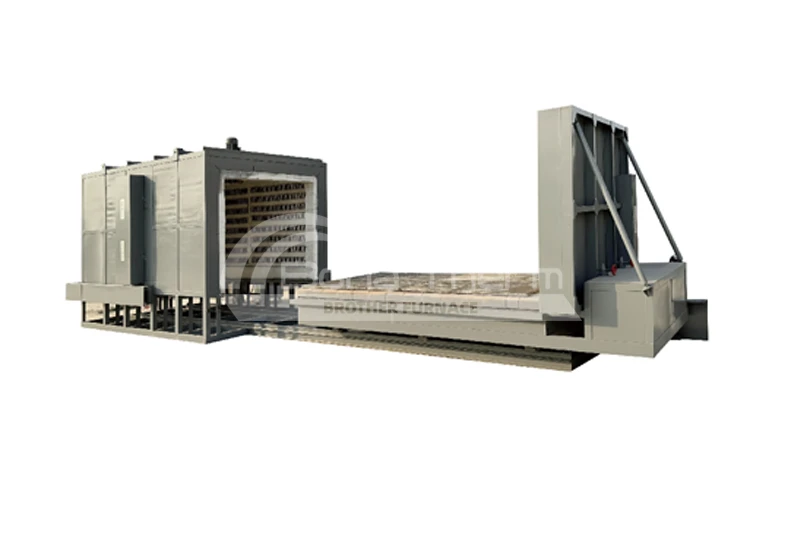

In industrial production, the heat treatment process is crucial for enhancing the properties of materials and extending the service life of products. As technology continues to advance, heat treatment equipment has undergone a remarkable evolution. The design concept of the car bottom tempering furnace, also known as a bogie annealing furnace or a bogie heat treatment furnace, focuses on improving productivity and energy utilization. The furnace structure is made of high-strength steel, which ensures the stability and durability of the equipment. The furnace can be lifted and transported in one piece, simplifying the transport process and installation steps.

-

Why Electrically Heated Bogie Hearth Furnaces Are Essential for High-Powered Industrial Applications

Discover the benefits of electrically heated bogie hearth furnaces for high-precision heat treatment, metalworking, and sintering, offering efficiency, precision, and energy savings.

-

The Role of Bogie Hearth Heat Treatment Furnace in Industrial Heat Treatment

Heat treatment is a critical process in the manufacturing of metal components, where precise temperature control and consistent heating are essential to achieve desired mechanical properties such as hardness, toughness, and durability. The bogie hearth heat treatment furnace is one of the most widely used systems for heat treating large and heavy parts, providing an efficient solution for industrial-scale heat treatment needs.

-

Ceramic Shuttle Furnace: In-depth Analysis of its Key Role in Ceramic Heat Treatment

In ceramic material manufacturing, the ceramic shuttle furnace plays a vital role in heat treatment, directly influencing product quality. With advanced heating, atmosphere control, and precise temperature regulation, it ensures ideal microstructure and superior performance during the sintering process.

-

Industrial Muffle Furnaces: Essential Equipment for Precision in High-Temperature Applications

An industrial muffle furnace is a crucial piece of equipment used in various high-temperature applications, from metallurgy and ceramics to environmental testing and research. Known for its ability to provide controlled, uniform heat, this furnace type has become indispensable across industries requiring precise thermal processing. Muffle furnaces have evolved significantly over the years, transitioning from simple, open-hearth units to highly sophisticated, energy-efficient models that can withstand extreme temperatures. This evolution in furnace technology has driven improvements in product quality, process efficiency, and workplace safety. In this article, Brother Furnace will explore the key features, applications, and benefits of industrial muffle furnaces, helping you understand why these furnaces are so essential in modern industry.