1000℃ Trolley Heat Treatment Furnace Supplied to Russia

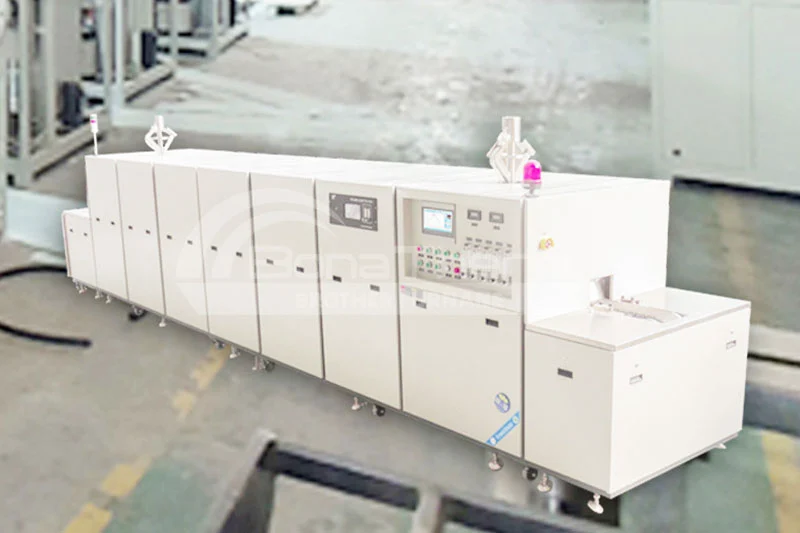

In the field of industrial heating equipment, the demand for efficient and reliable solutions continues to grow. Our company, a leader in electric furnace manufacturing, has successfully delivered a state-of-the-art trolley heat treatment furnace to a renowned steel processing plant in Russia. This case study highlights the specifications, advantages, and impact of this installation on the client's operations.

Customer Background

The client is a leading steel manufacturer in Russia, specializing in the production of high-quality steel components for various industries, including automotive, construction, and machinery. As part of their continuous improvement efforts, they sought to enhance their heat treatment processes to ensure superior material properties and increased production efficiency.

Project Requirements

The client required a heat treatment solution capable of handling heavy loads and providing precise temperature control for various steel components. Their primary goals included:

1. Improved Thermal Efficiency:

The furnace needed to provide uniform heating to reduce thermal gradients and ensure consistent treatment outcomes.

2. High Load Capacity:

The design had to accommodate significant payloads, with a requirement of 800 kg.

3. Advanced Control Systems:

The client desired features that allowed for precise temperature and time controls, facilitating repeatable and reliable heat treatment cycles.

4. Reduced Energy Consumption:

An energy-efficient solution was essential to minimize operational costs.

Feedback of Customer

Last month, the trolley heat treatment furnace that is up to 1000℃ was officially put into operation. After a period of usage, the client provided feedback on the equipment:

"The furnace you designed for our company has significantly improved the mechanical properties of the treated steel components, and the load capacity fully meets our requirements. The maximum temperature of 1000°C is also sufficient for our applications. What surprised us the most is the robust design of the furnace; it is much sturdier than the previous furnace we used, demonstrating the high-quality materials and excellent welding techniques you employed."

Conclusion

This successful project underscores our commitment to providing innovative solutions tailored to the specific needs of our clients. The trolley heat treatment furnace delivered to Russia exemplifies our expertise in creating advanced heating solutions that enhance productivity and efficiency. As we continue to expand our global presence, we remain dedicated to providing our clients with top-quality products and exceptional service.

Contact Us for the Perfect Solution

For more information on our electric furnace solutions or to discuss your specific requirements, please visit our website Brother Furnace, or contact our sales team. We look forward to partnering with you to enhance your industrial heating processes.