Introduction

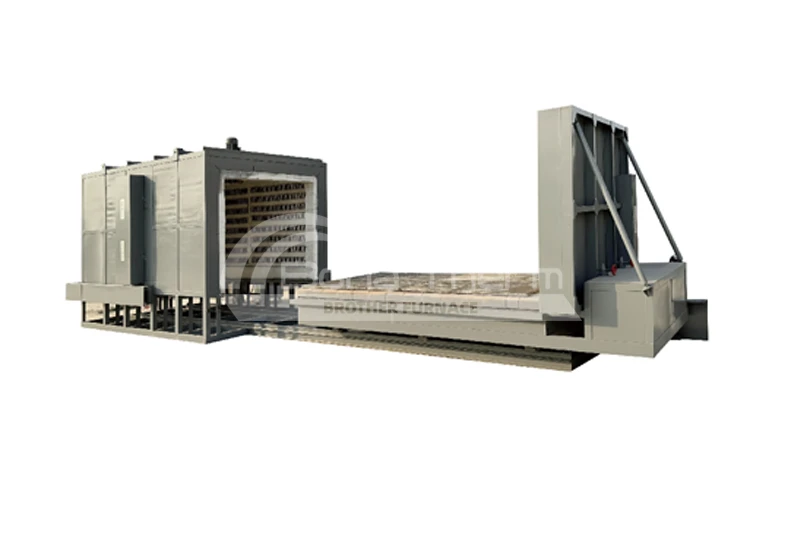

This equipment is widely used in universities, scientific research institutes, industrial and mining enterprises to do high-temperature sintering, metal annealing, chemical industry, metallurgy, ceramics, new material development, organic matter ashing, etc., and can also be used in the production and experiment of military industry, electronics, medicine, special materials, etc. Generally, it is divided into box furnace, non-metallic electric heating element box furnace, metal electric heating element box furnace, etc., and the workpiece is generally heated in the air medium, and there is no mechanized device for feeding and discharging.

RX3 series chamber furnace heat treatment furnace is mainly suitable for quenching, normalizing, annealing, quenching and tempering heating of carbon steel, alloy steel and other workpieces, and is also suitable for heat treatment of various small parts, springs, molds, etc. The new energy-saving furnace lining is adopted, which saves more than 20% energy compared with the old products, and has the advantages of fast heating and small loss of empty furnace.

Technical parameter

Model | Power(kW) | Voltage(V) | Phase | Max temperature(℃) | Chamber size L×W×H(mm) | Max loading capacity(Kg) |

|---|---|---|---|---|---|---|

RX3-15-9 |

15 |

380 |

1 |

950 |

600×300×250 |

80 |

RX3-30-9 |

30 |

380 |

3 |

950 |

950×450×350 |

200 |

RX3-45-9 |

45 |

380 |

3 |

950 |

1200×600×400 |

400 |

RX3-60-9 |

60 |

380 |

3 |

950 |

1500×750×450 |

700 |

RX3-75-9 |

75 |

380 |

3 |

950 |

1800×900×550 |

1200 |

RX3-20-12 |

20 |

380 |

3 |

1200 |

650×300×250 |

80 |

RX3-45-12 |

45 |

380 |

3 |

1200 |

950×450×350 |

200 |

RX3-65-12 |

65 |

380 |

3 |

1200 |

1200×600×400 |

400 |

RX3-90-12 |

90 |

380 |

3 |

1200 |

1500×750×450 |

700 |

RX3-115-12 |

115 |

380 |

3 |

1200 |

1800×900×550 |

1000 |