Introduction

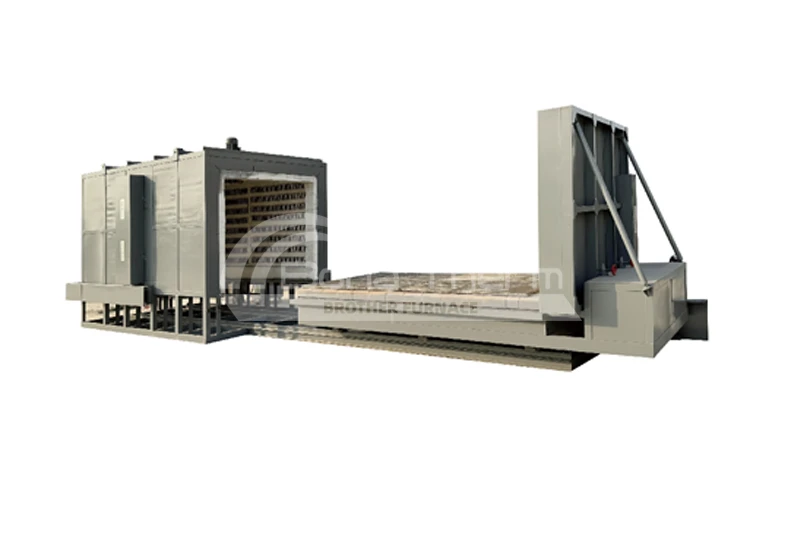

The mesh belt annealing protective atmosphere sintering furnace is mainly used for sintering the inner and outer surfaces of stainless steel pipes and nickel alloy pipes, copper-based powders, iron-based powders, copper-nickel alloy pipes, etc., and is also suitable for batch of small and medium-sized mechanical parts such as standard parts, bearings, chains, self-tapping screws, textile hardware, hand tools, elastic pads, various textile needles, and sewing needles for carburizing, carbonitriding, quenching and other heat treatment in the control atmosphere.

Features

● The heating furnace is made of heat-resistant stainless steel, with good structural strength, small thermal deformation and long service life.

● The mesh belt material is braided with imported heat-resistant steel wire.

● The refractory material is made of all-fiber ultra-light material for heat insulation and insulation, and the furnace has good thermal insulation performance.

● The transmission mechanism is simple and reliable, and the speed of the mesh belt is steplessly adjustable.

● The temperature control system automatically completes the setting of the PID parameters of the furnace temperature, the control is stable and reliable, and the temperature control system adopts the double meter system according to the new international electrotechnical standard.

● The production line is equipped with a reliable mechanical transmission system, all of which are automatically controlled by PLC programming, and equipped with fault self-diagnosis function.

Technical Parameter

serial number | Furnace size (length × width × height) ( mm ) | rated power ( kW ) | Rated temperature ( ℃ ) | Belt running speed ( mm/min ) | Belt width ( mm ) |

|---|---|---|---|---|---|

1 |

3000×350×150 |

60 |

1150 |

20~200 |

300 |

2 |

4000×450×150 |

90 |

1150 |

20~200 |

300 |

3 |

4000×550×180 |

100 |

1150 |

20~200 |

500 |

4 |

5000×650×200 |

120 |

1150 |

20~200 |

600 |

5 |

6000×650×200 |

150 |

1150 |

20~200 |

600 |