Working Process of Bogie Annealing Furnace

The Bogie annealing furnace is one of the most commonly used industrial devices, holding a significant place in industrial production due to its capacity for heavy-duty workpieces, precise temperature control, and efficient automated operation. So, how does a bogie annealing furnace work? Let's unveil the process.

What is Annealing?

Before understanding the bogie annealing furnace, let's first learn about the annealing process. Annealing involves heating a workpiece to a specific temperature, holding it at that temperature for a certain period, and then slowly cooling it down.

What is the Purpose of Annealing?

The purpose of annealing is to heat the workpiece to austenitize it and then perform pearlitic transformation, achieving a structure close to equilibrium. The main objectives are:

· Reduce the hardness of the workpiece, increase plasticity, and facilitate machining and cold deformation processing.

· Make the chemical composition and structure of the workpiece more uniform, refine grains, improve the performance of the workpiece, or prepare the structure for quenching.

· Eliminate internal stress and work hardening to prevent deformation and cracking.

Working process of Bogie Annealing Furnace

The working principle of the bogie annealing furnace is as follows:

Loading the Workpiece

The metal workpieces to be processed are loaded onto a movable bogie. This bogie is usually equipped with high-temperature-resistant materials to withstand the high temperatures during the annealing process.

Moving the Bogie

The bogie is pushed or pulled into the furnace chamber. The furnace chamber is a high-temperature-resistant enclosed space designed to distribute heat evenly.

Heating Stage

The heating system inside the bogie annealing furnace is activated. The heating system typically consists of gas burners or electric heating elements. The system gradually raises the temperature inside the furnace to the required annealing temperature. Precise control is needed to ensure uniform temperature rise.

Soaking Stage

Once the temperature inside the furnace reaches the set point, the system maintains this temperature for a period. This stage is called the soaking stage. The duration of the soaking stage depends on the type of metal and the size of the workpiece. The purpose is to ensure the internal temperature of the metal workpiece is uniform, allowing the grain structure to change, thus improving the ductility and toughness of the material.

Cooling Stage

After the soaking stage, the furnace temperature starts to decrease slowly. Cooling can be achieved through natural cooling or a controlled cooling system to regulate the cooling rate. Slow cooling is to avoid internal stress and deformation of the metal.

Unloading

Once the furnace temperature drops to a safe range, the bogie is pulled out, and the metal workpieces are unloaded, ready for subsequent processing or inspection.

The Main Components of the Bogie Annealing Furnace

Furnace Chamber

An enclosed space made of high-temperature-resistant materials provides a uniform heating environment.

Bogie

A movable platform for carrying workpieces, usually made of high-temperature-resistant and high-strength materials.

Heating System

Gas burners or electric heating elements are responsible for providing heat.

Temperature Control System

Includes temperature sensors and controllers for precisely adjusting and monitoring the furnace temperature.

Insulation Materials

Insulating materials cover the furnace chamber and bogie to reduce heat loss.

Cooling System

Used to control the cooling rate, preventing deformation of the metal during cooling.

Exhaust System

The exhaust system of the bogie annealing furnace is used to expel waste gases from the furnace chamber, keeping the air inside clean.

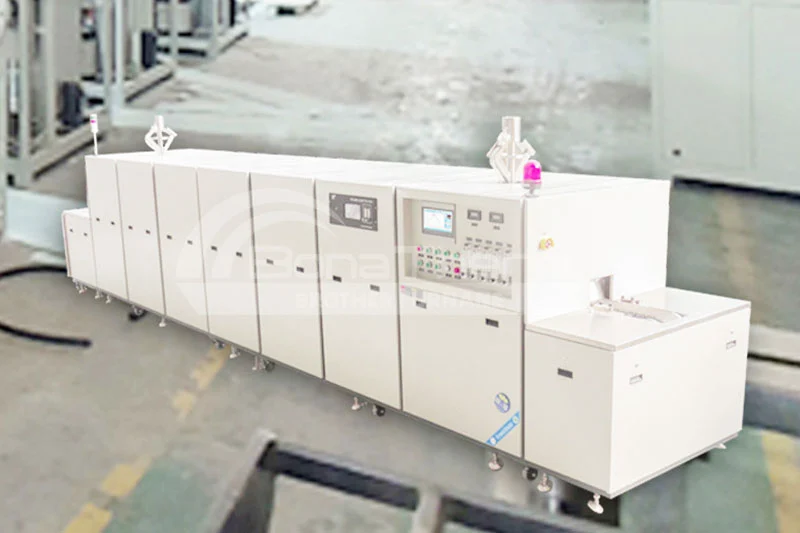

Brother Furnace's Trolley Annealing Furnace

Brother Furnace's bogie annealing furnaces are energy-saving, periodic operation furnaces primarily used for the annealing heat treatment and heating of steel castings, automotive parts, rolls, steel balls, metal structures, and welded parts at temperatures ranging from room temperature to 900℃. These furnaces feature a robust structure for overall lifting and transport, an all-fiber construction, and a multi-zone temperature control design to ensure uniform furnace temperature. The bogies are electrically operated and equipped with multiple safety devices to ensure safe and efficient operation. Additionally, Brother Furnace offersvacuum annealing furnaces equipped with a vacuum system for annealing materials under vacuum conditions.

Summarize

Due to their robust design and advanced technology, bogie annealing furnaces are widely used in high-demand industrial fields such as metallurgy, automotive manufacturing, and aerospace. Feel free to inquire about any questions regarding annealing furnaces and the annealing process.