A Comprehensive Guide to Bogie Hearth Furnaces

What is a bogie hearth furnace? Many people may have heard of bogie hearth furnaces as equipment widely used in industrial heat treatment processes, but do they fully understand their functions and features? This article will provide a detailed introduction to bogie hearth furnaces, covering their functions, features, structure, and categories to help you gain a comprehensive understanding of these essential industrial tools.

The origin of the bogie hearth furnace

To accommodate the heat treatment of large and heavy workpieces and to reduce labor intensity, the bottom of a chamber furnace was made movable, resulting in the bogie hearth furnace. Compared to chamber furnaces, bogie hearth furnaces include additional components such as a powered bottom (for furnaces with electric heating elements on the floor), a sealing device for the trolley, and a driving device for the trolley's movement. Broadly speaking, any furnace with a movable bottom can be classified as a bogie hearth furnace.

High temperature Bogie hearth furnaces are commonly used for annealing, normalizing, and tempering large and mass-produced castings and forgings. Due to their relatively poor sealing, additional electric heating elements are installed under the trolley floor or on the furnace door and thick walls to compensate for lower floor temperatures. To enhance temperature uniformity and heat transfer speed, fans can be installed at the top of the furnace. If necessary, low-temperature bogie hearth furnaces may also include air circulation devices and multi-zone controls.

The trolley can be designed with a tilting mechanism to further reduce labor intensity and improve production efficiency. This tilting is achieved by a motor driving a sector gear at the bottom of the trolley through a three-stage reduction mechanism. After normalizing, the workpiece can be easily unloaded by tilting the trolley at an angle (45°-60°). If a quenching tank is placed next to the furnace, the workpiece can be automatically directed into the tank for quenching after tilting. The entire process can be computer-controlled.

Characteristics of bogie hearth furnace

1. Loading Trolley Design

The loading trolley facilitates easy loading and unloading of workpieces, simplifying operation.

2. Uniform Heating Fans

Large bogie hearth furnaces are equipped with uniform heating fans for more even heating.

3. Efficient Heating System

Equipped with efficient heating elements (such as electric, gas, or oil heating), bogie hearth furnaces offer rapid heating and high thermal efficiency, quickly reaching the desired temperature.

4. Precise Temperature Control

Advanced temperature control systems with high-precision sensors and instruments monitor and control the furnace temperature in real-time, ensuring accurate and stable heat treatment processes.

5. Automation

Automation systems enable programmed control and automatic operation, simplifying processes, reducing human intervention, and enhancing productivity and product quality.

6. Versatility

Suitable for various heat treatment processes like quenching, tempering, annealing, and aging, bogie hearth furnaces can handle different materials and are widely applicable.

7. Safety Features

Equipped with multiple safety devices, such as over-temperature protection, overload protection, and emergency stop mechanisms, ensuring safe and reliable operation.

The structure of the bogie hearth furnace

This series of bogie hearth furnaces consists of two parts: furnace body and electric control.

Furnace Body: The furnace body includes the shell, lining, heating elements, door, and trolley. The door lifting and trolley movement are driven by electric reduction mechanisms. The bottom plate is made of heat-resistant cast steel and can be optionally equipped with a tilting unloading mechanism.

Electrical Control: The electrical control part manages temperature and mechanical operations, controlling heating, trolley movement, and door lifting, with self-locking protection.

What processes does the bogie hearth furnace support?

High-temperature bogie hearth furnaces typically operate between 300℃ and 1400℃ and are used for processes such as low-temperature tempering, stress-relieving annealing, quenching, normalizing, high-temperature annealing, and sintering. Here are the detailed applications:

Quenching

Bogie-type heat treatment furnaces suitable for quenching steel and non-ferrous metals (like copper and aluminum), enhancing hardness and strength through rapid cooling.

Tempering

Post-quenching, tempering involves heating metals to a temperature below their quenching point and then slowly cooling to reduce brittleness and increase toughness.

Annealing

Annealing involves heating metals to a certain temperature, maintaining them, and then slowly cooling them to soften the metal, improve its mechanical properties, and relieve internal stress. Bogie hearth furnaces are ideal for annealing large workpieces.

Aging

Used mainly for aluminum alloys and some copper alloys, aging involves heating metals to a specific temperature and holding them to improve their internal structure and properties.

Normalizing

Normalizing heats metals to an appropriate temperature and then air-cools them to relieve internal stress and improve structural properties, suitable for large workpieces.

Tempering and Nitriding

This process involves simultaneous tempering and nitriding to enhance surface hardness and wear resistance.

Stress-Relieving Annealing

Used to eliminate internal stresses from metal processing, with bogie hearth furnace providing uniform heating for large workpieces.

Sintering

For metal powder metallurgy processes, a bogie hearth furnace can be used for sintering metal powders into dense solid materials through high-temperature heating.

Learn more about Brother Furnace's Bogie Hearth Furnaces

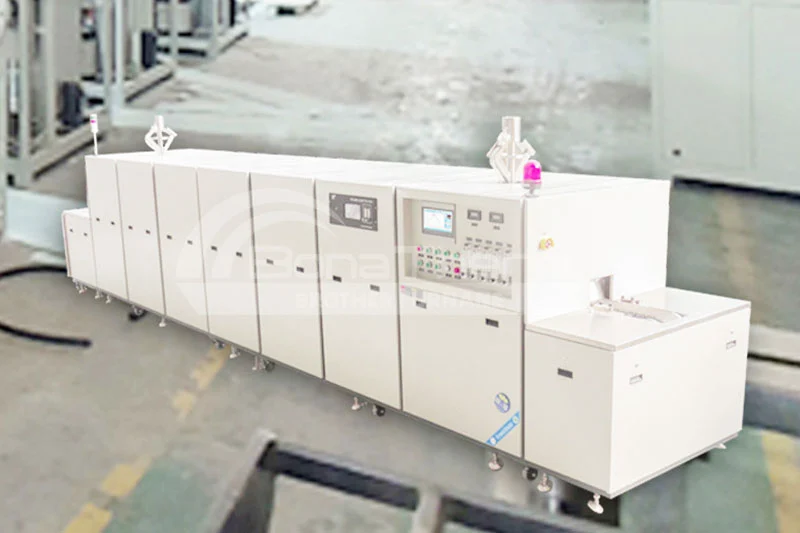

As a professional manufacturer of bogie hearth furnaces, Brother Furnace has achieved significant success, with exported bogie hearth furnaces praised for their stability and efficiency. Here are some of our trolley furnace types:

Brother Furnace's trolley furnaces can be divided into the following categories:

Chamber Heat Treatment Furnace

Bogie Hearth Tempering Furnace

Summarize

After reading this article, you should have a deeper understanding of bogie hearth furnaces. If you are considering purchasing a

bogie hearth furnace or are unsure if your operation requires one, feel free to contact us with your requirements. We will respond within 12 hours.